Here is an overview of the different stages of production of the home automation module and the MyShower.be software

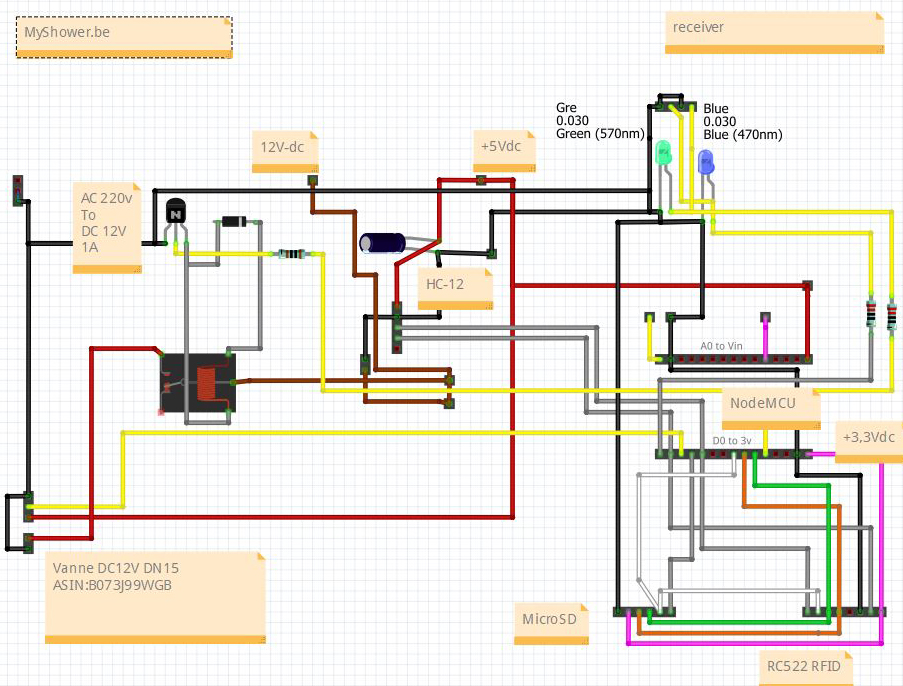

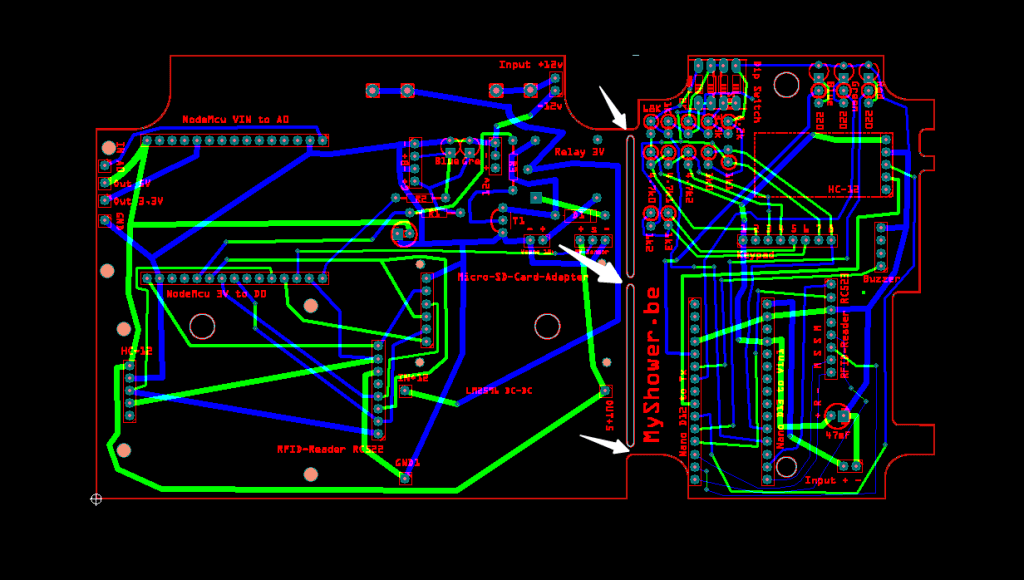

Receiver

Development of a block diagram with the Fritzing software

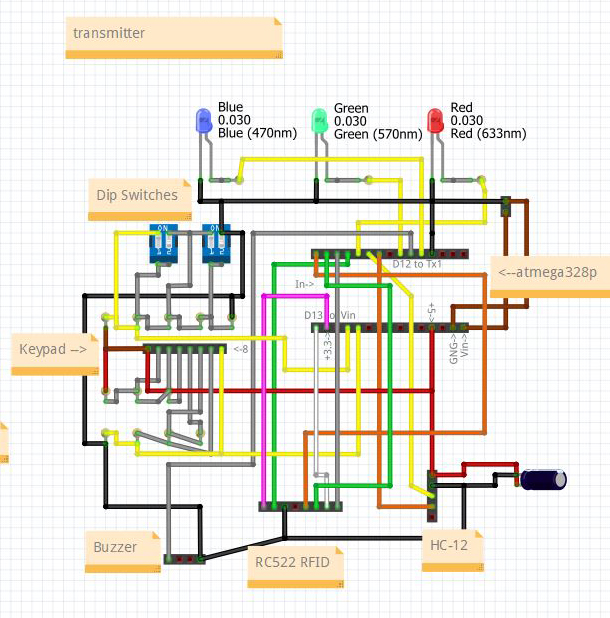

Transmitter

Development of a block diagram with the Fritzing software

Receiver

Creation of the schematic for the breadboard

Transmitter

Creation of the schematic for the breadboard

First tests of the components on a test board

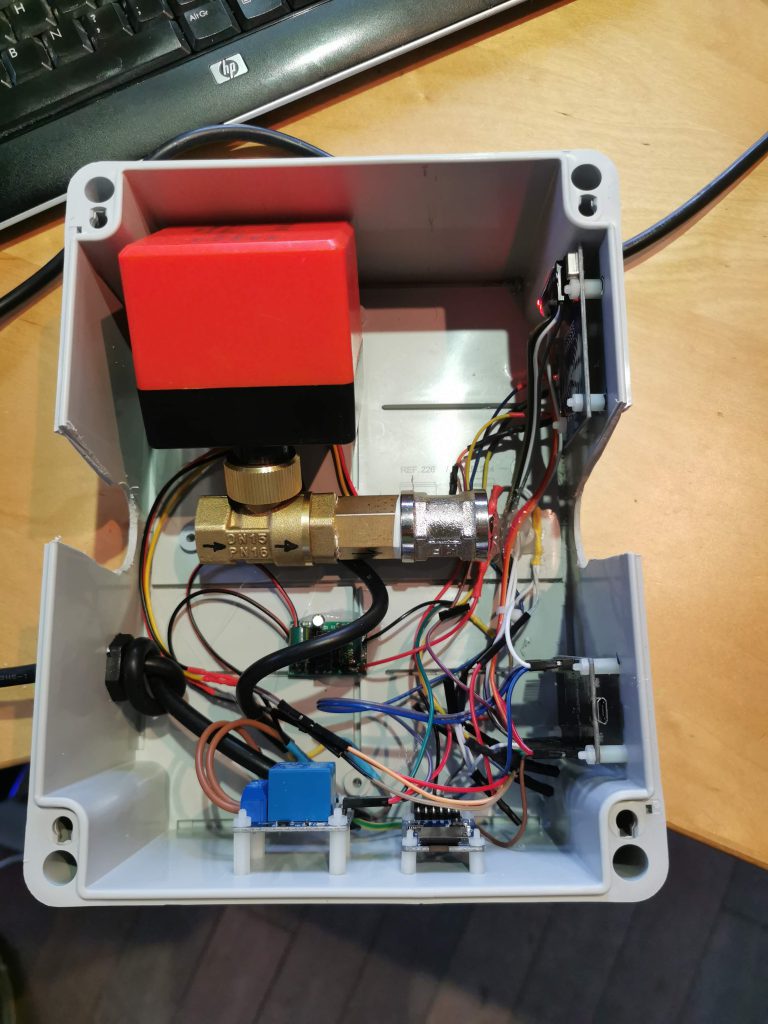

Prototype

Creation of a prototype

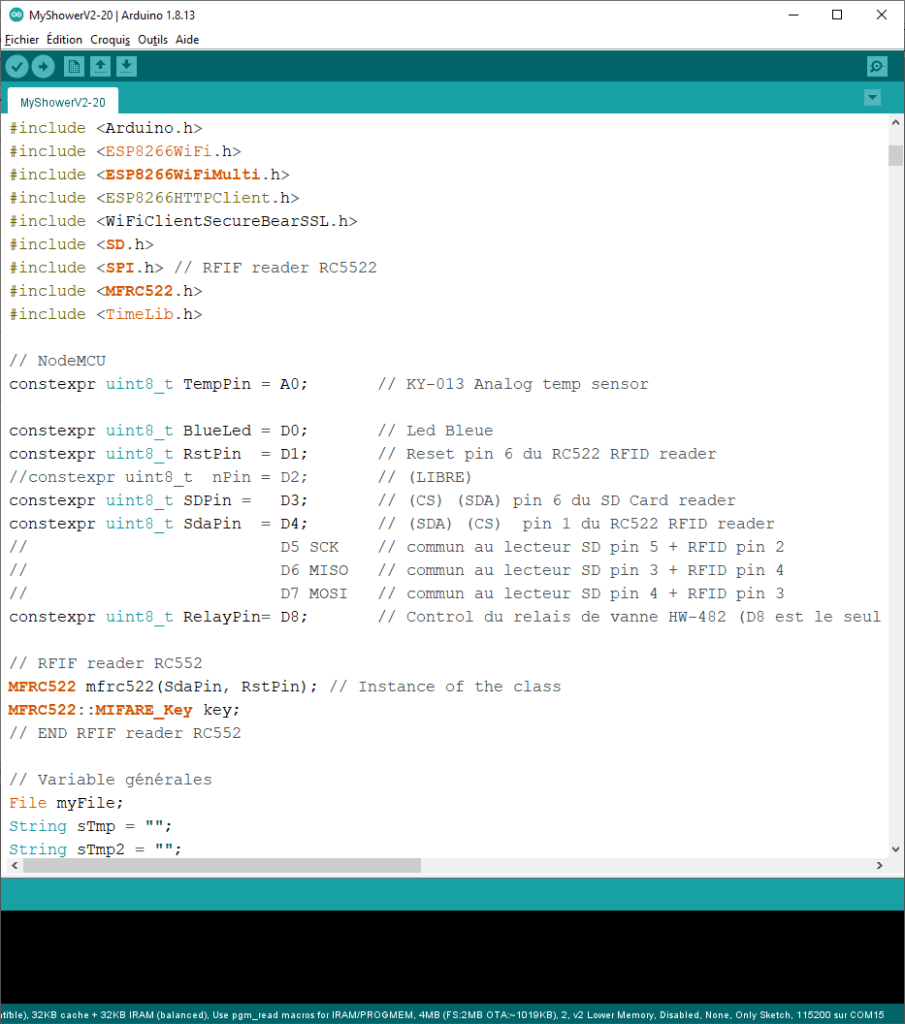

c++ software

Development of software to interpret sensor information and control the solenoid valve based on a Node-MCU V3 mini motherboard connected to WiFi

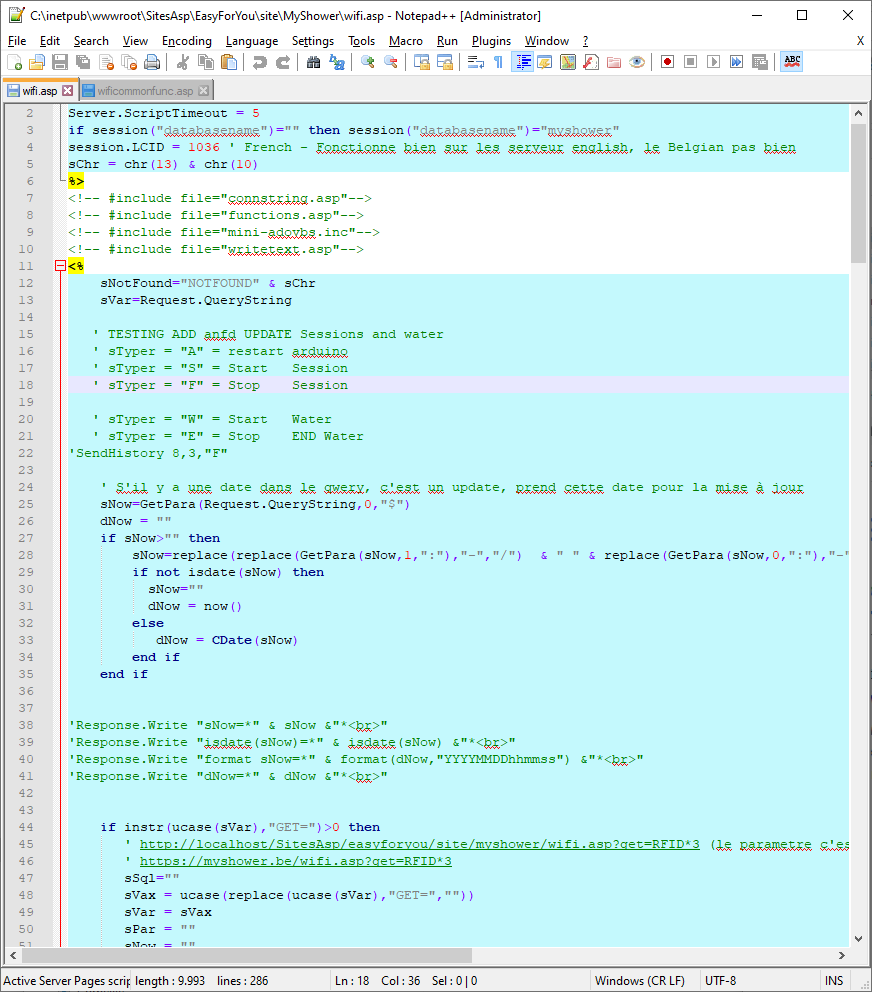

client server

Client-server software on the myshower.be website

Server: To manage the database

Client: To manage the opening from a mobile phone of shower sessions, activate the solenoid valve and consult the user’s history

The electronics in action:

During the development in C++ of the robotics module (domotics), all the steps and variables can be monitored in real time

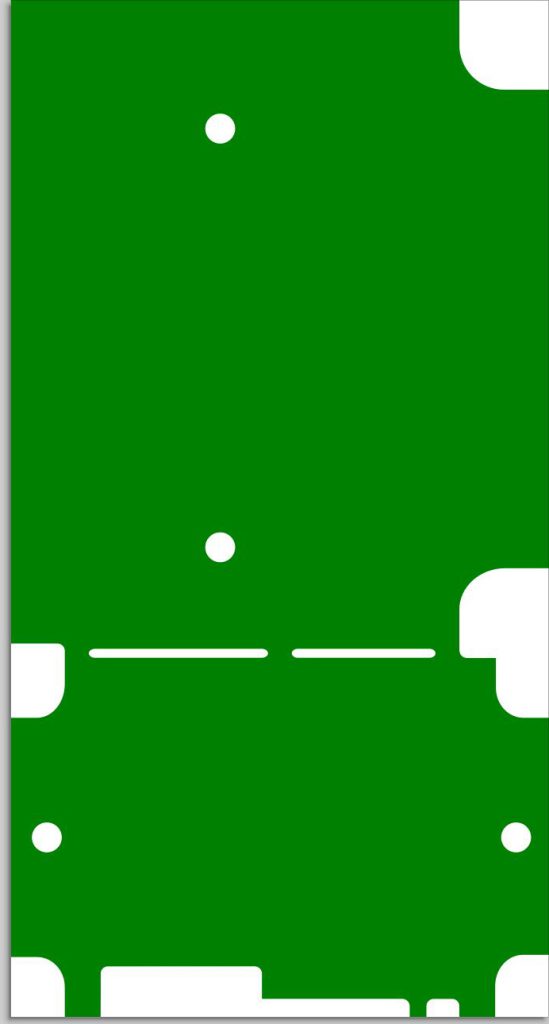

Creation of a cut-out format of the circuit board with the vector drawing software Inkscape

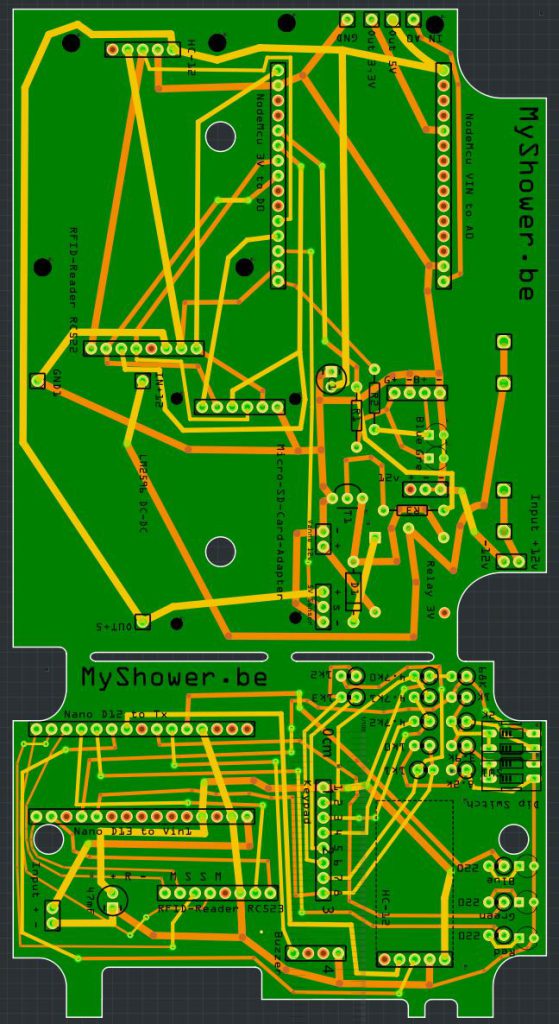

Creation of plan for the two layers circuit board in the Fritzing software

Circuit pre-press test before production in Taiwan

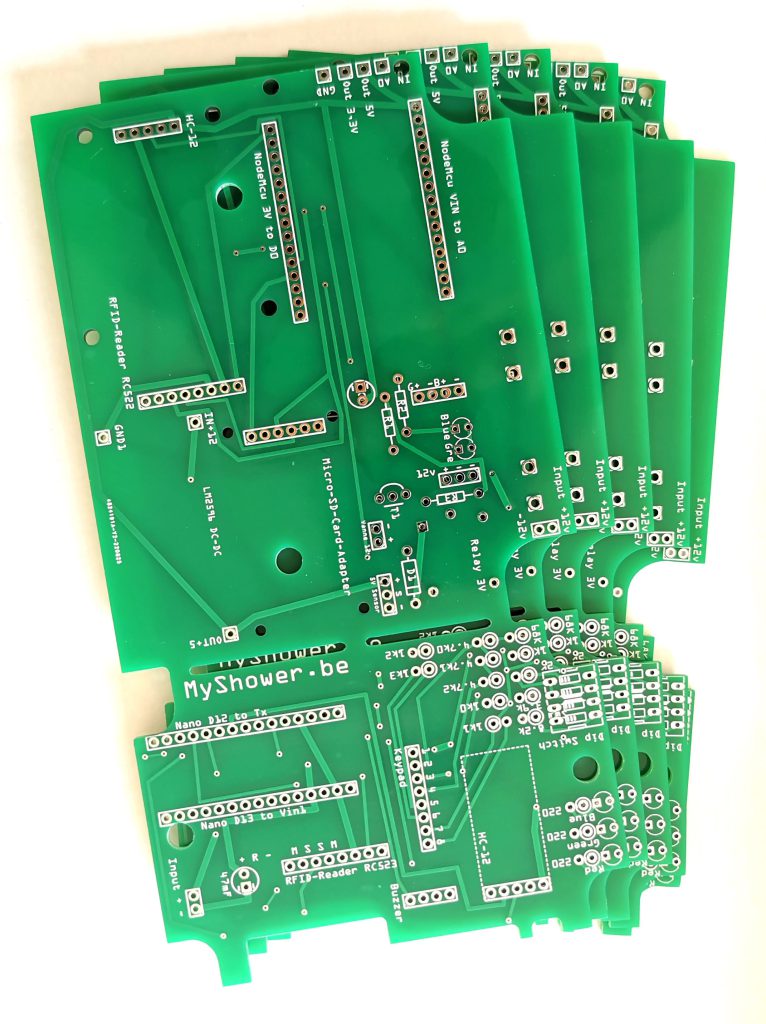

Receipt and verification of double-layer printed circuits

Soldering of components and connectors

Installing the Solenoid Valve and Receiver on the Shower Hot Water Line

Bathroom

Installation of the transmitter in its waterproof box with external keyboard for the pin code and RFID reader

(In principle, the user controls his shower session with his mobile phone, but in case of absence of internet, the session can be started via his RFID key or a pin code)